MIT engineers have developed a brand new system utilizing a sequence of sun-driven reactors to supply carbon-free hydrogen gas, considerably growing effectivity from 7% to 40%. Their modern train-like reactor design might make inexperienced hydrogen manufacturing scalable and economically possible.

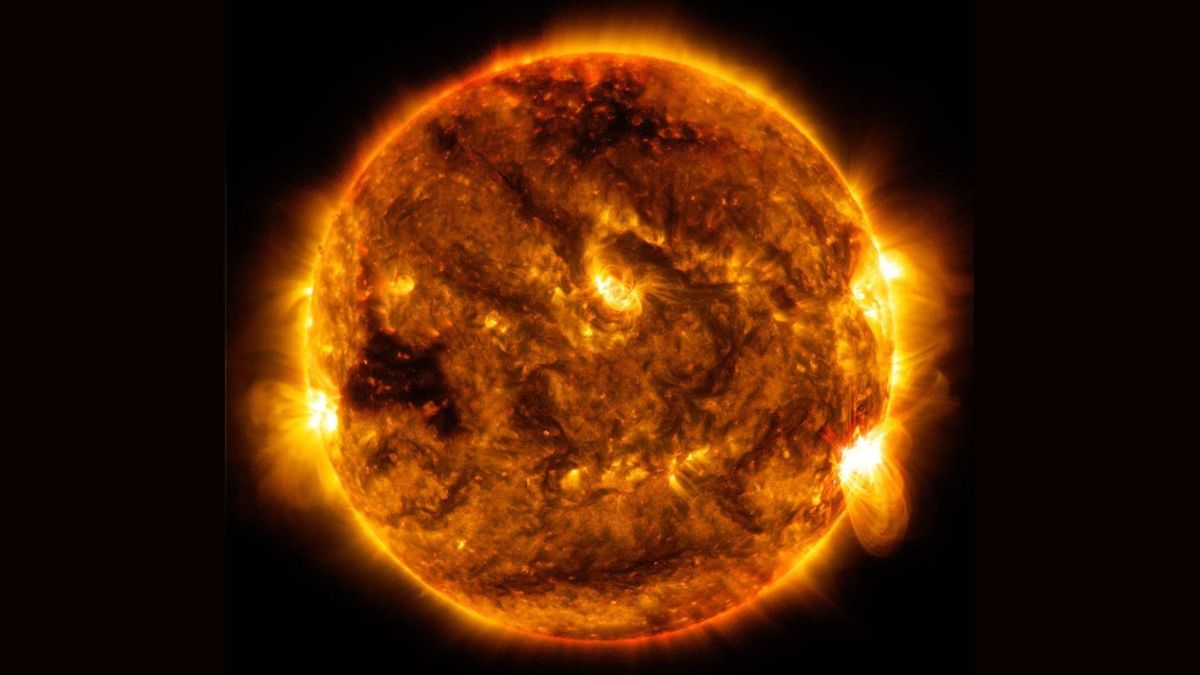

MIT engineers goal to supply completely inexperienced, carbon-free hydrogen gas with a brand new, train-like system of reactors that’s pushed solely by the solar.

In a examine lately printed within the Photo voltaic Power Journal, the engineers lay out the conceptual design for a system that may effectively produce “photo voltaic thermochemical hydrogen.” The system harnesses the solar’s warmth to immediately break up water and generate hydrogen — a clear gas that may energy long-distance vans, ships, and planes, whereas within the course of emitting no greenhouse gasoline emissions.

In the present day, hydrogen is essentially produced via processes that contain pure gasoline and different fossil fuels, making the in any other case inexperienced gas extra of a “gray” vitality supply when thought-about from the beginning of its manufacturing to its finish use. In distinction, photo voltaic thermochemical hydrogen, or STCH, gives a completely emissions-free various, because it depends totally on renewable photo voltaic vitality to drive hydrogen manufacturing. However to this point, present STCH designs have restricted effectivity: Solely about 7 % of incoming daylight is used to make hydrogen. The outcomes to this point have been low-yield and high-cost.

MIT engineers have developed a design for a system that effectively harnesses the solar’s warmth to separate water and generate hydrogen. Credit score: Courtesy of Ahmed Ghoniem, Aniket Patankar, et. al

In an enormous step towards realizing solar-made fuels, the MIT workforce estimates its new design might harness as much as 40 % of the solar’s warmth to generate that rather more hydrogen. The rise in effectivity might drive down the system’s general value, making STCH a doubtlessly scalable, reasonably priced possibility to assist decarbonize the transportation trade.

“We’re considering of hydrogen because the gas of the long run, and there’s a must generate it cheaply and at scale,” says the examine’s lead writer, Ahmed Ghoniem, the Ronald C. Crane Professor of Mechanical Engineering at MIT. “We’re attempting to realize the Division of Power’s objective, which is to make inexperienced hydrogen by 2030, at $1 per kilogram. To enhance the economics, now we have to enhance the effectivity and ensure a lot of the photo voltaic vitality we gather is used within the manufacturing of hydrogen.”

Ghoniem’s examine co-authors are Aniket Patankar, first writer and MIT postdoc; Harry Tuller, MIT professor of supplies science and engineering; Xiao-Yu Wu of the College of Waterloo; and Wonjae Choi at Ewha Womans College in South Korea.

Photo voltaic stations

Just like different proposed designs, the MIT system could be paired with an present supply of photo voltaic warmth, reminiscent of a concentrated photo voltaic plant (CSP) — a round array of a whole lot of mirrors that gather and replicate daylight to a central receiving tower. An STCH system then absorbs the receiver’s warmth and directs it to separate water and produce hydrogen. This course of may be very completely different from electrolysis, which makes use of electrical energy as a substitute of warmth to separate water.

On the coronary heart of a conceptual STCH system is a two-step thermochemical response. In step one, water within the type of steam is uncovered to a steel. This causes the steel to seize oxygen from steam, leaving hydrogen behind. This steel “oxidation” is much like the rusting of iron within the presence of water, however it happens a lot sooner. As soon as hydrogen is separated, the oxidized (or rusted) steel is reheated in a vacuum, which acts to reverse the rusting course of and regenerate the steel. With the oxygen eliminated, the steel might be cooled and uncovered to steam once more to supply extra hydrogen. This course of might be repeated a whole lot of occasions.

The MIT system is designed to optimize this course of. The system as a complete resembles a practice of box-shaped reactors operating on a round monitor. In apply, this monitor could be set round a photo voltaic thermal supply, reminiscent of a CSP tower. Every reactor within the practice would home the steel that undergoes the redox, or reversible rusting, course of.

Every reactor would first move via a scorching station, the place it will be uncovered to the solar’s warmth at temperatures of as much as 1,500 levels Celsius. This excessive warmth would successfully pull oxygen out of a reactor’s steel. That steel would then be in a “diminished” state — able to seize oxygen from steam. For this to occur, the reactor would transfer to a cooler station at temperatures round 1,000 C, the place it will be uncovered to steam to supply hydrogen.

Rust and rails

Different comparable STCH ideas have run up in opposition to a standard impediment: what to do with the warmth launched by the diminished reactor as it’s cooled. With out recovering and reusing this warmth, the system’s effectivity is simply too low to be sensible.

A second problem has to do with creating an energy-efficient vacuum the place steel can de-rust. Some prototypes generate a vacuum utilizing mechanical pumps, although the pumps are too energy-intensive and expensive for large-scale hydrogen manufacturing.

To deal with these challenges, the MIT design incorporates a number of energy-saving workarounds. To get well a lot of the warmth that might in any other case escape from the system, reactors on reverse sides of the round monitor are allowed to change warmth via thermal radiation; scorching reactors get cooled whereas cool reactors get heated. This retains the warmth throughout the system. The researchers additionally added a second set of reactors that might circle across the first practice, transferring in the wrong way. This outer practice of reactors would function at usually cooler temperatures and could be used to evacuate oxygen from the warmer internal practice, with out the necessity for energy-consuming mechanical pumps.

These outer reactors would carry a second kind of steel that may additionally simply oxidize. As they circle round, the outer reactors would take up oxygen from the internal reactors, successfully de-rusting the unique steel, with out having to make use of energy-intensive vacuum pumps. Each reactor trains would run repeatedly and would generate separate streams of pure hydrogen and oxygen.

The researchers carried out detailed simulations of the conceptual design and located that it will considerably increase the effectivity of photo voltaic thermochemical hydrogen manufacturing, from 7 %, as earlier designs have demonstrated, to 40 %.

“We’ve got to consider each little bit of vitality within the system, and find out how to use it, to attenuate the price,” Ghoniem says. “And with this design, we discovered that every thing might be powered by warmth coming from the solar. It is ready to use 40 % of the solar’s warmth to supply hydrogen.”

Within the subsequent 12 months, the workforce shall be constructing a prototype of the system that they plan to check in concentrated solar energy amenities at laboratories of the Division of Power, which is at present funding the venture.

“When absolutely carried out, this technique could be housed in just a little constructing in the course of a photo voltaic discipline,” Patankar explains. “Contained in the constructing, there might be a number of trains every having about 50 reactors. And we expect this might be a modular system, the place you may add reactors to a conveyor belt, to scale up hydrogen manufacturing.”

Reference: “A comparative evaluation of integrating thermochemical oxygen pumping in water-splitting redox cycles for hydrogen manufacturing” by Aniket S. Patankar, Xiao-Yu Wu, Wonjae Choi, Harry L. Tuller and Ahmed F. Ghoniem, 16 October 2023, Photo voltaic Power.

DOI: 10.1016/j.solener.2023.111960

This work was supported by the Facilities for Mechanical Engineering Analysis and Training at MIT and SUSTech.